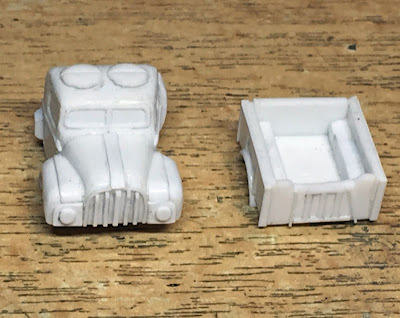

Progress on the Humber 1 ton Truck

This little model is one of those where I keep picking it up and putting it down, over and again. The main reason for this is that it is just so complicated with multiple compound curves where they curve in two directions at the same time. This isn’t so bad in a larger scale model, but in something this size, even a 10 thou error stands out like a sore thumb. Well, it does to me.

A lot of the time it’s been a case of cutting and filing to get a piece to the right shape, then adding bits of 10 thou plastic strip if I’ve filed away too much and doing it all over again, until eventually it is somewhere near the right shape.

There are still some small bits of detail to add to the cab, and then there’s the chassis, which is the same as the Humber Pig that I’ve already done in resin for The N Gauge Society, and I can use the wheels from the Pig as well. That just leaves the canvas tilt over the body, which I’ll make as a separate part.

Theses vehicles were widely used by the British Army in the 1950s and 60s, but were overly complicated and expensive, and were replaced in service by the various marks of Land Rover. They were used in the Suez crisis, and I have photos of them on the landing craft used in the operation. I also have a photo of one next to a Sycamore helicopter, which is included in the Revell kit of a US WWII, and German Navy post war landing craft. One reason for doing the canvas tilt as a separate part is that I can recall in the late 1960s and 70s seeing a number of ex-Army Humber Trucks used by garages as recovery vehicles, with just a simple A-frame on the back.

Talking of the N Gauge Society (NGS) resin models. I agreed to make four models for the NGS, and here is a photo of one of the test castings of the Bv206, which is the last of the four. This has now gone in to production and work is underway for a photo-etched sheet to go with it, and pewter track units from me..

Earlier this week I had another delivery of 25 kg of pewter from my metal supplier. I was expecting a price increase as the prices are set by the metal exchange that I believe work in dollars. However, I was very surprised to find that the price has actually gone down. It would appear that the Chinese are now using less tin and copper than they were a few years ago, which has brought the price down. This is matched by a price increase in the cost of the RTV-101 silicone rubber that I use to make the moulds. Hopefully, the two will balance each other, and so I’ll be able to hold my prices as they are for another year through 2020.

P.G. Models

No comments:

Post a Comment